Expert Interviews

- University Reviews

- Career Guide

Video Counseling

Video CounselingImportant Facts

- Ask any Question - CV Forum

Duties & Key Responsibilities of Production Manager [2026]

Isha Adhikari Jan 28, 2026 1.4K Reads

Individuals who are responsible for production management. He/she coordinates with the production team or manages the production and technical processes of the industry.

They also ensure that there must be an adequate amount of resources and that all the resources available are used accordingly without any wastage of resources.

They also have a responsibility to create a budget, allocate project expenses, and schedule significant human resources to ensure that the assigned tasks get completed by the projected deadlines. Therefore, hard-core professionalism and job specialization are a few of the production managers.

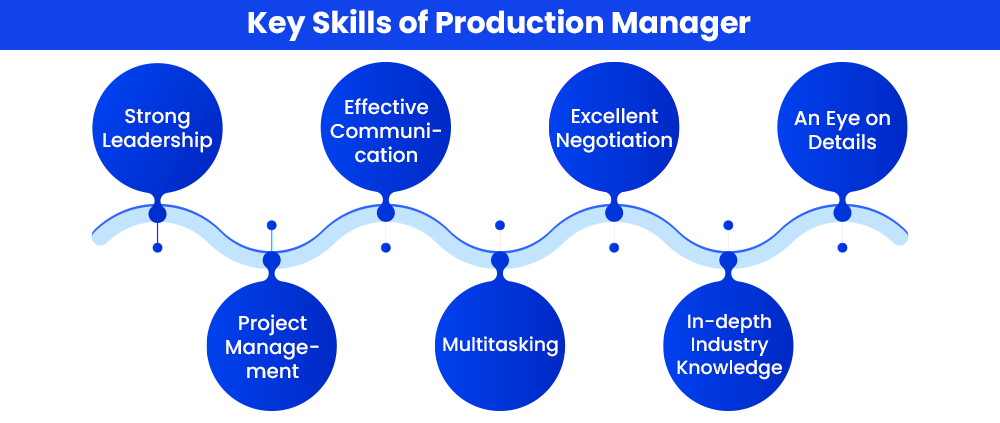

What Skills Are Needed For A Production Manager?

A production manager is an individual who is responsible for the production management of a business firm. Hence, a production manager is expected to know soft and technical skills to supervise the team. Here are a few listed skills that a production manager must possess:

- Strong Leadership Skills: A production manager must have robust leadership skills as their role is to lead the overall team. He/she should know how to manage and supervise the team effectively and make them finish the tasks before the deadline. They must know how to motivate the team, delegate tasks according to their strengths and weaknesses, and set the ultimate goals and objectives. Collaboration and teamwork are a few qualities of good leaders. Additionally, they also have a helping nature and know how to resolve team conflicts or employee disputes. Overall, there must be a positive and supportive working environment for the team members to accomplish the organizational goals and objectives.

- Good Negotiation Skills: Having excellent negotiation skills is very important for any production manager. Since they need to coordinate with the suppliers, vendors, and internal departments. Hence, it becomes easier for the production manager to secure favorable terms for raw materials, machinery, or services, which is essential for keeping production costs low. This skill also helps in building healthy and positive relations that guarantee efficiency and effectiveness in the work. Negotiation skills also help the production manager in setting an effective cost and deadline for the production within the organization.

- An Eye For Detail: Since a production manager acts as a leader, therefore, it is even more crucial for them to have an eye for detail. It is expected from them that they will check the functioning of the production process very carefully. This involves meticulously overseeing production schedules, machinery operations, quality control, and safety standards. Since a missing element or process can impact the production process of the organization negatively. These minor mistakes can also lead to major negative consequences, including an increase in cost, delay in production, frequent shifts in project deadlines, etc., which can affect customer satisfaction and the company’s overall profitability. It is expected to pay close attention to inventory levels, machine maintenance, and workforce productivity to identify the issues early. Being detail-oriented is extremely important, as it helps to complete the deadline on time.

- A Calm Demeanour: A production manager must have a calm demeanor because they need to handle a huge team, meet deadlines, and ensure positive yet serene working conditions within the organization. The ability to remain calm under stress enables a production manager to think clearly, solve problems efficiently, and lead the team effectively without creating panic or frustration. Whether it’s equipment breakdowns, delays in the supply chain, or workforce challenges, a calm approach helps maintain order and keeps the production process running smoothly. A good manager is likely to handle any situation or uncertainty without compromising on the quality of the timelines.

- Effective Communication Skills: The next quality that a production manager must have is effective verbal and written communication skills. Since they act as leaders in their team; that’s why they need to have coordination with different departments. They also need to convey their messages or information to different individuals, including workers, supervisors, vendors, and upper management. Along with that, they have to convey clear messages or instructions to their team members to get the tasks finished on time. Good communication also includes listening to feedback from employees and addressing any concerns they may have. It also ensures transparency in the work, and any type of biasedness is not practiced within the organization. In addition, production managers must report progress, challenges, and results to management, requiring strong written and verbal communication abilities.

- Project Management: Project management is one of the most important skills every production manager has. Since they need to oversee the different phases of the production within the organization, including planning, scheduling, budgeting, executing, etc. This involves creating efficient workflows, allocating resources, and managing timeframes to ensure that production targets are met. Effective project management includes risk-taking, effective planning, etc. A production manager needs to complete the aligned tasks within a budget that leads to long-term success.

- Multitasking: A production manager must be a multitasking person, as they need to manage a whole team which leads to numerous responsibilities and tasks on their hands. Also, they need to be super-active since they need to keep a track record of each employee within the team. Being a multitasker doesn’t mean they need to solve only team disputes or disruptions; they also need to address several other problems, such as machinery breakdowns or supply chain delays, without disrupting overall productivity. By effectively handling multiple responsibilities at once, a production manager ensures that the production process runs smoothly, meets deadlines, and maintains quality standards.

- Industry Knowledge: Having in-depth knowledge of the industry or in which field they are working is a fundamental quality of a production manager. They need to be super knowledgeable in which project they are working on, as they need to inform teams and let them know their roles and responsibilities accordingly to get the tasks done before or on the deadline dates. They must know ever-evolving industry trends and modern technologies. This knowledge includes an understanding of the specific manufacturing processes, machinery, materials, and technologies relevant to the industry. Staying updated on industry advancements allows production managers to adopt innovative methods, optimize efficiency, and maintain competitiveness. Along with that, having a track record of trending topics or modern technologies helps them to address different technical issues, manage the resources wisely, and ensure that the production aligns with the latest quality standards. A well-informed production manager enhances overall productivity and operational success.

What Are The Major Responsibilities Of A Production Manager?

Being a production manager, individuals may have a few major responsibilities that they need to fulfill.

These responsibilities include production planning, production control, quality control, method analysis, inventory control, plant layout, work measurement, and other functions:

- Production Planning: The first and foremost responsibility of a production manager. It means making a plan about the resources, labor, time, and other machinery required for production within the organization. They develop production schedules, allocate tasks, and ensure that deadlines are realistic and achievable. They also assess capacity, predict potential bottlenecks, and plan for contingencies to prevent disruptions. Effective production planning ensures that production runs smoothly, minimizes waste, and maximizes the use of resources while meeting customer demand on time and within budget.

- Production Control: Production control is another responsibility of the production manager; it includes budgeting, costing, quality needed, and checking on the availability of resources that are available or needed to complete a production efficiently or on time. An excellent production manager tracks progress, identifies deviations from the plan, and takes corrective actions when necessary. They need to manage several other things too, which include managing workforce performance, machine efficiency, and material usage. The end objective of production control is to ensure that all the tasks are completed on time, within budget, and with full efficiency. Hence, it is expected that a production manager keeps a track record of each aspect, from budget needed, resources available, labor and time needed, and setting deadlines.

- Quality Control: Quality control is another aspect for which a production manager is fully responsible. This involves implementing quality checks at various stages of production, from raw materials to finished goods. They need to work closely to ensure the quality of the task and involve different team departments to get the work done efficiently and effectively and meet the deadline. They also analyze quality data to identify patterns of defects and initiate process improvements. By maintaining strict quality control, production managers protect the company's reputation, reduce waste, and ensure customer satisfaction.

- Method Analysis: Process or method is the fundamental part of any task. Even in the production process, method analysis plays a crucial role. Being a production manager, it is important to optimize the process of aligned tasks and to identify the areas where improvement is needed. The goal is to enhance productivity, reduce waste, and ensure that production methods are cost-effective and sustainable. By reviewing existing procedures and implementing more efficient techniques or technologies, production managers help streamline operations, reduce lead times, and improve overall efficiency. Method analysis is an ongoing process that ensures the production system remains adaptable and competitive in a changing market.

- Inventory Control: Inventory control means to manage the inventory needed in the production process. It is expected from an exceptional production manager to manage an adequate inventory of raw materials, components, and finished goods. They must ensure that all the needed resources, including labor and raw materials, are timely available to ensure the timely delivery of the task. They should monitor inventory levels to prevent overstocking or shortages, which can lead to production delays or excess costs. They work closely with the procurement and supply chain teams to maintain optimal stock levels, reorder materials when necessary, and implement systems to track and manage inventory effectively. Efficient inventory control reduces costs, avoids disruptions, and keeps production running smoothly.

- Plant Layout: Plant layout means to arrange the equipment, machinery, and workstations within the production facility. A well-designed layout optimizes the flow of materials and workers, minimizes waste, and enhances productivity. Production managers are responsible for assessing the current layout and making adjustments to improve efficiency, safety, and space utilization. They ensure that the layout facilitates smooth transitions between different stages of production, reduces material handling time, and allows for proper maintenance of equipment. A well-organized plant layout is essential for achieving high productivity and maintaining a safe working environment

- Work Measurement: The work measurement includes analysis and evaluation of time and efforts needed to complete tasks on a timely basis. This helps in balancing workloads, optimizing staffing levels, and ensuring that production targets are realistic and achievable. By measuring and analyzing work performance, production managers can identify bottlenecks, reduce idle time, and enhance overall production within the organization or business firm. Accurate work measurement contributes to better workforce management and ensures that production operates smoothly within defined timeframes.

- Other Functions: Except for the core responsibilities, the production manager must fulfill some other tasks too. They need to check the employees' reports and motivate them from time to time to increase work efficiency. They need to collaborate with different departments to keep all the aligned tasks in sync and to align production goals with company objectives, such as procurement, logistics, and quality assurance. Additionally, they oversee staff training, performance evaluations, and fostering a positive work environment to keep production teams motivated and effective.

What’s the Highest Qualification For A Production Manager?

To become an exceptional production manager, one needs to complete a UG program in business management, pharmaceutical technology, biotechnology, mechanical engineering, or electrical and electronics engineering. Although it may vary depending on the industry, you are willing to work.

Conclusion

Working as a production manager is a tough yet rewarding job in itself. One has to be more patient and knowledgeable, as they need to work on a vast range of projects and coordinate with several types of people. Furthermore, collaborating with different teams and departments, keeping the status of the various processes in the overall production, and maintaining positive working management are also responsibilities of the production manager.

FAQs (Frequently Asked Questions)

These are the five functions of a production manager:

- Demand Forecasting & Planning

- Quality Control & Assurance

- Resource allocation and management

- Maintenance and equipment management

- Production Scheduling

These are a few listed key skills for a production manager:

- Efficient Communication

- Strong Leadership

- Problem-Solving

- Decision-Making Ability

- Calm Nature

Production management's responsibilities are summarized by the 5M's:

- Men

- Machines

- Methods

- Materials

- Money

The most important KPIs for production managers revolve around:

- Performance

- Quality

- Maintenance

- Efficiency

The salary of a production manager in India ranges from INR 3 LPA to 28 LPA. The average salary package for a production manager in India may vary from INR 10 to 14 LPA.

3 Years of Experience / Narrator

With 3 years of experience in content writing and copywriting and keen interest in voiceover and scripting, I, Isha Adhikari, am passionate about content creation and narration.

Every query is essential.

Our team of experts, or experienced individuals, will answer it within 24 hours.

Recommended for you

Tired of dealing with call centers!

Get a professional advisor for Career!

LIFETIME FREE

Rs.1499(Exclusive offer for today)

Pooja

MBA 7 yrs exp

Sarthak

M.Com 4 yrs exp

Kapil Gupta

MCA 5 yrs exp

or

Career Finder

(Career Suitability Test)

Explore and Find out your Most Suitable Career Path. Get Started with our Career Finder Tool Now!

ROI Calculator

Find out the expected salary, costs, and ROI of your chosen online university with our free calculator.