Expert Interviews

- University Reviews

- Career Guide

Video Counseling

Video CounselingImportant Facts

- Ask any Question - CV Forum

Amul Case Study - How Amul Does Its Supply Chain?

Isha Adhikari Sep 2, 2025 1.2K Reads

The main reasons behind the world's largest dairy cooperative society are that the efficient supply chain and a focus on quality have made Amul grow from a small Gujarat-based cooperative to a world leader in dairy. This helped the company become one of the world's most successful dairy brands because of its empowerment of farmers, quality control, innovative marketing, and sustainability. Amul is fast-growing its networks across the world, and its cooperative style of operation and supply chain innovativeness will remain a major success factor.

Amul is already a popular brand in India that is known for its top-quality milk products and has taken a position in the kitchen of Indians. Amul is a brand owned by The Gujarat Co-operative Milk Marketing Federation (GCMMF), which was founded on 14th December 1946, and became a rather international global dairy conglomerate. Its quality and price are only some of the contributing factors to its success, since it has an excellent supply chain system.

This blog will discuss the way Amul works on its supply chain, the characteristics that make it special, and the things that other businesses can learn from this model.

Amul - The Taste of India: An Overview

The success story of Amul is such that its well-structured supply chain system is also well defined. The brand came into existence when the abuse of middlemen in the milk and dairy business was on the rise on a large scale, and there was a need to eradicate them at the root. Amul is a cooperative society in which the farmers (the producers) are the owners of the company, and the harvest is shared among them.

Amul has evolved to be one of the biggest dairy producers in the world today. It produces and sells more than 400 products, which include milk, butter, cheese, ice cream, and chocolates, among many other ready-to-eat products. The brand happens to be present in more than 50 countries, and its network of over 3.6 million dairy farmers stretches out.

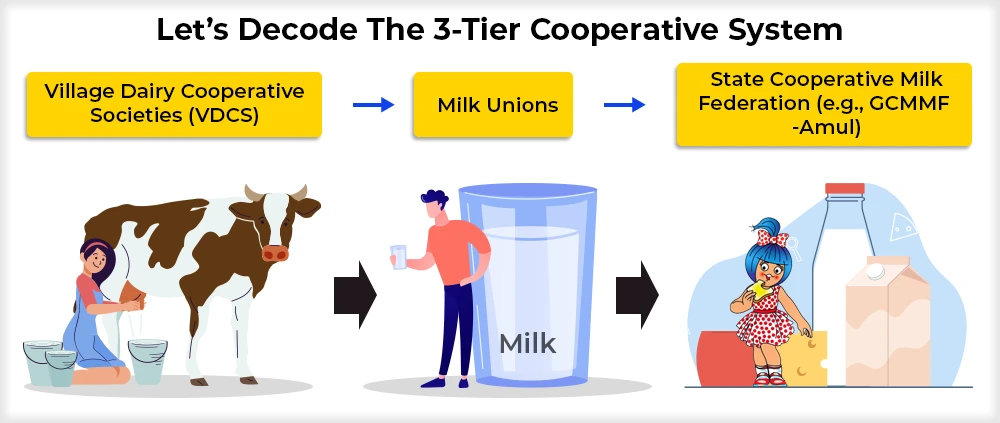

Amul: The 3-Tier Cooperative System or Anand Pattern

The Amul 3-Tier Cooperative System, or the Anand Pattern, is a very unique and successful form of Indian dairy cooperative organizational structure. It increases the power of producers of milk to millions of people by looking after the ownership and control in the entire milk supply chain, including collection and marketing. The system is fair to the farmers, and the products that are delivered to consumers are quality in terms.

The 3-Tier Cooperative System

- Village Dairy Cooperative Societies (VDCS): The grassroots is where the individual milk producers in a village link and join together to become a cooperative. They also do the collection of milk daily; they test the quality of milk and pay farmers directly. They also avail themselves of necessary services such as veterinary and cattle food.

- Milk Unions: These unions are established by the VDCS in a district, and they take up the milk of village societies. They are in charge of the mass-processing of milk into other dairy products, controlling the transportation as well as offering high-tech support facilities and training to the societies of the village.

- State Cooperative Milk Federation (e.g., GCMMF - Amul): This is the topmost body and consists of the District Milk Unions within a state. It deals in the marketing, branding, and distribution of all dairy products and distributes them with a unified brand name, such as Amul, so that it reaches far in the market and innovates its products.

Advantages of AMUL’s 3-Tier Cooperative System or Anand Pattern

- Farmer Empowerment & Fair Returns: It cuts out the middleman, and the milk producers will directly own the business and get a fair and steady price on the milk that they produce, which enhances their lives immensely.

- Quality Assurance at Source: The system gives high quality assurance at the very source since quality testing and training of farmers occur in the villages so that the end products of high quality will be obtained by consumers.

- Economic Scale/Efficiency: With millions of small-scale farmers supplying milk to the cooperative, they can enjoy economic scale in terms of processing, marketing, and distribution, making operations in the cooperative very efficient and economic.

- Market reach and brand building: The highest level, such as GCMMF, will efficiently market and distribute the products across the country and the world so as to create a powerful and recognized brand name, say Amul, and have wide availability.

- Rural Development & Resilience: The system should bring about rural development through employment activities, infrastructural development, and better self-reliance of the local farmers, as well as collective strength to face the challenges.

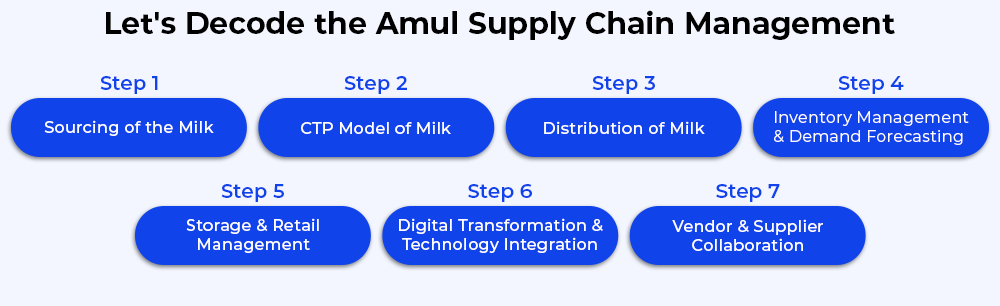

Let’s Decode the Supply Chain Strategy of Amul

Every manufacturing company has a foundation of several pillars, such as time management and efficiency, and the most important, supply chain management, that help it to execute the operations and to grow, and so does Amul. Amul’s supply chain is founded on a few pillars that ensure performance is efficient, rapid, and cost-efficient. The company has an integrated supply chain along which farmers and end consumers are connected in a single chain with processing plants. Its supply chain strategy includes the following key elements:

-

Step 1: Procurement- Sourcing the Raw Milk

Amul started at the grassroots level by sourcing the raw milk directly from the dairy farmers. The cooperative model enables Amul to obtain milk directly at its dairy farm from the farmers in the Gujarat region and neighboring states as well. This type of supply chain rules out intermediaries so that the suppliers (farmers) get good prices for their milk and the customers get better dairy products at reasonable prices.

- High Network of Farmers: Amul can also be said to be one of the greatest dairy cooperatives in the world, having a network of more than 3.6 million dairy farmers who sell milk to Amul.

- Ideal Pricing Model: Amul uses the mechanism of the cooperative model to make sure that farmers are paid fairly and on time. This gives strength to local farmers and becomes a win-win situation between producers/employers on the one hand and consumers on the other hand.

- Milk Collection Centers (MCCs): Amul has more than 18,000 milk collection centers in where farmers deliver their milk. Such centers are distributed in Gujarat and elsewhere.

Step 2: The CTP Model (Collection, Transportation & Processing) of Milk

After milk has been collected by the dairy farmers, it is directly taken to any of the numerous processing plants of Amul. The system of processing is very automated and efficient, which is fast and of high quality.

- Cold Chain Logistics: Milk is a highly perishable product; thus, ensuring a cold chain is of importance. Amul has formed a cold chain system that carries the raw milk to its processing plants and final products to people.

- Bulk Milk Chilling Unit (BMCU): These bulk milk chilling units facilitate the maintenance of the milk quality at low temperatures (below 4°C) so as to inhibit the growth of bacteria. The milk is later relayed to regional plants, which carry on with the processing process.

- Processing Plants: Amul has a wide network of 70+ dairy processing plants located across the country. The processing technology to handle milk, as well as the production of value-added products such as butter, cheese, ghee, and ice cream, is the latest technology in these plants.

Step 3: Distribution of Milk Across the Central & Regional Network

Amul has a regional and centralized distribution channel. The supply chain management at the company ensures products are in the market in the least time possible, either to retailers or consumers.

- Amul Distribution Centers: The firm has established more than 50 distribution centers in India, where finished products are kept, and they help in bringing quick delivery.

- Regional Distribution: In the regions that are near the production units, Amul distributes milk and dairy products directly to regional markets by using its own logistics network. In the case of long-distance locations, Amul contracts with third-party logistics companies to have appropriate and direct delivery.

Amul's distribution model comprises the following:

- Wholesale Distribution: Amul has a vast and strong network of wholesale distributors through whom it distributes to retailers, hotels, and institutions.

- Retail Distribution: The products of Amul are made available in more than 500,000 retail stores countrywide. The company has many distribution channels, such as direct selling, e-commerce, and retail outlets, to ensure the accessibility of the product very broadly.

Step 4: Managing Inventory & Forecasting Demand of Milk by Amul

Amul has a strong inventory management and demand forecasting team that helps in making the supply chain management of Amul more efficacious. Proper demand prediction can enable Amul to operate production in such a way that it avoids overstocking or the shortage of goods, which may result in waste.

- Real-Time Tracking: Amul also employs high-end tracking systems to keep track of stocks and tracking of goods in the network. This assists the company in responding fast to fluctuations in demand and supply.

- Demand Forecasting: The Amul supply chain team uses sophisticated statistical modeling and data analysis tools to forecast the demand and base the production accordingly. This will make the company not experience excess or insufficiency.

Step 5: Amul’s Milk Cold Storage & Retail Management

The preservation of the cold chain between the processing units and the retail outlets is one of the largest problems in the dairy industry. Amul has also invested mainly in cold containers and transportation systems so that its products are kept fresh from the factory to reach the consumer.

- Cold Storage Warehouses: Amul has cold storage warehouses spread across India that have been used to store the finished dairy products. These warehouses make sure that wares are accommodated at a proper temperature up to the time they dispatch them.

- Retail Partnering: Amul has very direct contact with many modern retail outlets in India and mom-and-pop stores as well. This alliance will mean that the brand will have good visibility and reach to consumers.

Step 6: Amul’s Milk Digital Transformation & Technology Integration

Amul has used much technology to maintain the supply chain over the past years to grow its efficiency and to make the operations smooth. This has been a digital revolution that has helped the company in cutting down on costs, increasing the pace of deliveries, and improving customer satisfaction.

- Auto-Processing AI Technology: The dairy processing plants of Amul are also armed with the latest automation technology, such as Artificial Intelligence (AI) and Machine Learning (ML) algorithms, to enhance the productivity of the manufactured product.

- Data Analytics: Amul employs data analytics software to streamline inventory levels, demand variance forecasting, and routing of the milk and dairy products.

- ERP Systems: The Enterprise Resource Planning (ERP) systems are usually used by many entities to track their inventory status, sales, and complete performance so that the business can grow on a large scale.

Step 7: Milk Vendor & Supplier Collaboration

The partnership with suppliers and vendors is one of the major aspects of success for Amul. The company makes sure that it has good terms with its suppliers in order to access good-quality raw materials and other components used in the company, e.g., the packaging materials and the flavoring agent.

- Supplier Diversity: To be ready and reduce the chances of any risk, Amul identifies more than one supplier who would provide packaging material, ingredients, and other supplies.

- Vendor Relationship Management (VRM): The company practices close association with the suppliers in a bid to track quality, time consistency of supply, and strike good terms.

Who are the Suppliers of Amul Milk?

Dairy farmers who deliver raw milk to Amul are the most common suppliers of this company. Amul has arranged these farmers into milk cooperatives and has guaranteed them reasonable prices for their milk. Along with milk, Amul also gets other raw materials such as sugar and flavoring agents, packaging material (plastic, cartons, etc.), and other ingredients used in their dairy products. Amul is connected to numerous suppliers whose services (supplying these other ingredients and packaging and processing equipment) they remember well.

How Does Amul Ensure Its Supply Chain Sustainability?

The world is now focusing more on sustainability in its business, and Amul is not left behind. The supply chain of the company is keen on environmental sustainability, social accountability, and economic sustainability.

-

Environmental Responsibility

- Water Conservation: Amul advocates the use of water in milk production and milk processing. Most of the processing plants of Amul have facilities for water treatment in which the water is recycled to get use.

- Energy Efficiency: Amul owns renewable sources of energy and energy-efficient technologies in its factories to mitigate its carbon footprint.

-

Supporting Farmers

Fair Pay: With direct contact with farmers, Amul makes sure that their products have a fair price, and hence, a more equal supply chain would become available.

Training and Support: Amul also trains the farmers on how to increase milk production and milk quality. Financial and technical support is also provided to them by the company.

-

Reducing Wastage

Amul has come up with very effective technologies that minimize wastage in each level of the supply chain. To maintain the freshness of the company's dairy products, the company applies just-in-time (JIT) inventory systems and a cold chain and shortens the interval between production and delivery.

After setting up a massive dairy market in India and other big countries. This brand is all set to make its debut in the European market. They have partnered with the dairy corporation of Spain (COVAP) to launch their products in European countries.

What is the Secret behind Amul’s Success?

The cooperation model, or you can say the innovative Anand pattern, quality control, and consumer trust, are the secrets of the success of Amul. Among the reasons that have made it successful are as follows:

- 3-Tier Cooperative Model (or Anand Pattern): Amul also makes sure that the farmers who provide milk are always co-owners of the cooperative, thus having some interest in the success of the company.

- Quality Assurance of Milk & Other Dairy Products: Amul observes high quality control standards in each step, including milk collection, processing, and packing, and makes available to consumers safe and fresh products.

- Innovative Marketing by the Advertising Mascot “Amul Girl”: Its advertising mascot, the Amul Girl, has made Amul remain relevant with buyers in their minds. Its artistic advertisements usually use the most recent events and fashion, which renders the brand familiar. Also, the “Utterly Butterly Delicious… Amul” slogan was a big hit that, till now, everyone knows very well. Another best thing about this brand is that they connect the recent or trending topics with their mascot or with the Amul Girl, whether it’s The Golden Boy Neeraj Chopra or the 100th birth anniversary of legendary Raj Kapoor, “Aaj bhi dilon pe Raj hai.”

- Affordable Costing: Amul has a pricing strategy that makes its product affordable to the consumers, hence being a mass-market product. The effective pricing of Amul Milk and other dairy products helped a lot in making the brand more accessible to all levels of consumers, ranging from Tier-1 to Tier-3 cities.

- Increasing the Scope of Products: The ability of Amul to diversify the production of products has enabled consumers to get all their milk, butter, ice cream, cheese, and chocolate needs from a single point.

- Assured Sustainability: The brand Amul has ensured the sustainability of its supply chain activities through its concentration on environmental, social, and economic considerations.

What is the Main Objective of Amul?

Empowerment of dairy farmers and delivery of quality dairy products to the consumers at manageable prices is the foremost activity of Amul. Amul wants to stamp out intermediaries through its cooperative model so that farmers will receive their fair share of profit. Meanwhile, it also makes sure that consumers get quality dairy products at affordable prices.

Why is the Amul Pattern of Economy Popular Across the World?

This cooperative model used by Amul is quite popular around the globe for the following reasons:

- Dairy Farmer Empowerment: The brand Amul involves ensuring farmers receive direct payment for their milk, which offers them a stable income and eliminates exploitation by middlemen.

- Sustainability: This is because Amul has introduced sustainability in terms of acquiring and reselling with energy-efficient production and the use of less waste to ensure that corporations across the globe promote its example.

- Price & Quality: Amul can offer low-price but high-quality products, which enjoy a wider market and suit the needs of both low-income and middle-income earners. This feature helps in making it more reasonable and accessible to the target market audience.

- Social Advantage: The model of Amul makes it socially positive, as it generates local jobs by connecting the local farmers to the manufacturing process, making the economy of the area prosper.

- Scalability: Another thing about the Amul model that makes it an ideal move is that it is scalable and flexible, and it is an example to other nations trying to better their dairy industries. This feature not only helps in scaling the production but also helps in improving the overall quality of the brand.

Master the Supply Chain Strategies just like Amul

Are you also impressed by Amul's supply chain strategies and would like to implement them in your business to enhance your brand? To excel in this area, you must complete courses such as an online MBA in supply chain management and an online MBA in supply chain & logistics (dual). Those who already have their UG degree in supply chain management or have passed their bachelor’s and master’s and want to pursue their doctorate in this field can choose a DBA doctorate degree in supply chain management online.

Yes, it is true that courses like these not only help you excel in the theoretical aspect of supply chain management but also help you learn about the practical side of supply chain management.

Conclusion

The significant role of Amul in becoming a world leader in the dairy industry is attributed to its well-established supply chain, its highly effective cooperative model, and its insistence on quality. This marketing strategy on empowering farmers, quality control, new marketing, and sustainability has given the company the status of one of the most successful dairy brands in the world. As Amul continues to associate growth with the world, its cooperative strategy and the innovation in its supply chains will be the major players in its success.

FAQs (Frequently Asked Questions)

Amul practices a 3-tier cooperative model to supply milk and other dairy products. This strategy not only keeps the process in sync but also helps in cutting down the middlemen and providing the milk and dairy products to consumers straight from the dairy farmers.

The milk is first collected from the village dairy cooperatives, then processed at the district milk unions, and then it is distributed by the state federation or the Gujarat Co-operative Milk Marketing Federation (GCMMF).

The issue with the Amul supply chain includes multiple things, such as delays in logistics, challenges in managing the cold chain, and the major problem that includes a proper coordination with thousands of villages that help them in collecting huge quantities of milk

The suppliers of Amul include almost 36 lakh dairy farmers who help in the milk supply. These 3.6 million farmers mainly belong to Gujarat, and the rest of them are from other Indian states.

The value chain of Amul contains the following steps:

- Collection of Milk

- Processing

- Packaging

- Distribution

- Marketing

Countries like India, Australia, the USA, the UAE, Singapore, etc. Overall, Amul exports its milk and dairy products to over 30+ countries. In fact, now Amul has entered into their partnership with Spain’s dairy corporation (COVAP) so that they can supply products all over the European countries

The brand AMUL stands for Anand Milk Union Limited. It was established on 14 December 1946. Its headquarters are in Anand, Gujarat, India.

3 Years of Experience / Narrator

With 3 years of experience in content writing and copywriting and keen interest in voiceover and scripting, I, Isha Adhikari, am passionate about content creation and narration.

Every query is essential.

Our team of experts, or experienced individuals, will answer it within 24 hours.

Recommended for you

Tired of dealing with call centers!

Get a professional advisor for Career!

LIFETIME FREE

Rs.1499(Exclusive offer for today)

Pooja

MBA 7 yrs exp

Sarthak

M.Com 4 yrs exp

Kapil Gupta

MCA 5 yrs exp

or

Career Finder

(Career Suitability Test)

Explore and Find out your Most Suitable Career Path. Get Started with our Career Finder Tool Now!

ROI Calculator

Find out the expected salary, costs, and ROI of your chosen online university with our free calculator.