Expert Interviews

- University Reviews

- Career Guide

Video Counseling

Video CounselingImportant Facts

- Ask any Question - CV Forum

What is Industrial Safety? - Definition & Example

College Vidya Team Jan 11, 2025 24.5K Reads

Industrial Safety is defined as safety management practices or precautions ensured during industrial crucial situations. In simple terms to avoid any human incident or machinery failure prevention measures are must which can be planned to deal in hazardous situations.

What is Industrial Safety? - Definition & Example

Industrial Safety ensures the safety and security of workers, industrial materials which can cause damage if not taken care of properly. Under these the commercial unit safety measures, how to plan and execute in critical situations functioning takes place. To maintain safety measures and handle hazardous situations . No matter whichever type of workplace it be Industrial or Corporate, the main motive or training provided to the students is to keep that particular environment in a safe zone .Safety at workplace, workers, factory materials safety measures are ensured.

For example : There are fire extinguishers in schools, offices, malls, metro, theatres to avoid any fire mishap. These safety measures are ensured by the safety officer who has planned and analysed what can harm a large count of people.

Why is Industrial Safety Necessary?

A tendency is not always like a static approach and this question why is industrial safety necessary is a most important one, the necessity is of safety and security and above all if there is a solution to prevent safety measures than why not get it onboard. Organisations are aware that the mishappenings should be avoided as the safety options are available for the employee and workstation safety zone.

- Industrial Safety ensures that there are strict protocols.

- It Increases the Employee awareness for having all safety measures.

- Planning of Industrial Safety will help to avoid hazardous situations.

- Human Loss and Industrial material loss can be controlled.

Explore Our Top Trending Articles

Objectives of Industrial Safety

Objectives are basically the goals or motto set to just function a smooth workstation. Environment should be stress free without a fear of any danger or hazardous situation. Implementations are all carried through the planning, and structuring it for the future cordance.

- To avoid and control scary workstation danger zones.

- To implement safety rules and protocols that an employee should follow.

- Analyse the risk factor that can be a reason for an accident.

- Cross-Check the tools functioning if you notice any kind of difficulty while the employee is working.

Importance of Industrial Safety

Importance is all related to the working and smooth functioning of the workstation. In recent years the organisation has realised that safety is something which needs to be kept on priority because the danger zone can harm the materials as well as the employee health and it's an negative repo for the company as it is assumed that the incident was due to ignorance of casualties. The organisation has understood that its is important to have an ethical safety and human sense where the employees can build a trust for working with dangerous tools.

- It increases the retention rate in physical working organisations.

- Compensation to employees' families cannot be matched to the human loss.

- The productivity does not affect as there are safety protocols for which company plans.

- Awareness and safety tools will be a habitual task and nobody will be pulled in critical situations.

Industrial Safety Certification Courses Online

The Industrial Safety field is practical as well as there are some of the blended course curriculum that are structured for the students. The certification is through the course completion and performance and on that basis the grades are granted to an individual. For the certification, students need to go acquire the practical training sessions online as well as offline mode. There are multiple courses and different programs of industrial training that a student can opt for their certification program. As the industrial certification course can help to manage work with organisations that have a difficult or dangerous work zone.

Industrial Safety Skills

Skills that can help to prevent the danger zone and to run a smooth environment requires a . Skills are something on the basis of which you can implement a safe working place. Industrial Safety requires some management, communication implementations skills which will help them to create a smooth safe working zone.

Skills are as follows :

- Preparation of Plans and Modification according to the situation demands

- Communication Skills should be excellent and should know basic languages rather than english

- Managing Skills should be smooth without any hustle or hectic situation

- Presence of Mind to keep safe zone in working area is essential

- Tackling rough situation without creating a anxious behaviour is must

Industrial Safety Roles & Responsibilities

There are a variety of roles and responsibilities as the whole working space is dependent on safety management that creates a safe zone and undoubtedly the risk factor should be 0.1%. For this a pre planned list and analysing method plays an mandatory role. Examination and Inspection is a coordinated work which an industrial safety officer should practise and the rules and regulations should be strictly conveyed to the workers as no one feels resuming work with experiencing hazardous incidents.

Roles are as follows :

- Examine the danger zone

- Prepare a awareness note

- Circulate and keep reminding the precaution measures to the workers

- Create a safety list posters and stick around workstations

Responsibilities are as follows :

- Make sure each and every worker is ensuring safety

- Check and maintain all the work station machines

- The working area should be examined at least Twice in a day

- Save Emergency contacts and backup tools to avoid serious hazard situations

Industrial Safety Jobs

Training practice can be implemented at work with live working exposure. In Industrial safety courses there are unlimited job options available for the students who want to start their professional journey. The demand for safety officers is increasing to maintain work station accident free. The government jobs are also available in the industrial safety field.

Job Profiles are such as :

- Safety Officer

- Health & Safety Manager

- Environment & Safety Manager

- Industrial Hygiene Manager

- Safety Engineer

- Safety Consultant

- Risk Manager

- Safety Manager

- Coordinator of loss control

Explore Some Career Related Article

Industrial Safety Salary

Industrial Safety has a variety of job profiles and attractive salary packages. The pay is the major factor which requires to be compared. For the initial salary an individual can expect 4 LPA to 6 LPA of salary package. The number can increase once the experience is built in a particular field as the growth is measured in terms of ability and capability.Depending on the designation the pay is distributed and accordingly the higher position can have a hike in salary.

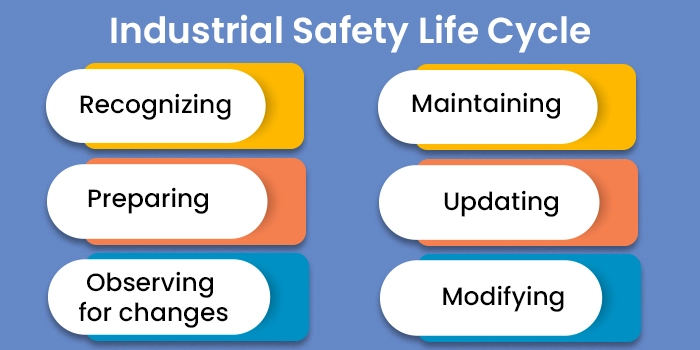

Industrial Safety Life Cycle

Life cycle is a routine which involves the safety plans, danger zones, precautions and the learning of how to manage the critical situation is all about the course study, which a student goes ahead throughout the learning cycle. Maximising some of the industrial hazard moments and analyse what measures were not implemented? What were the possibilities to save the hazardous incident?

The life cycle each day brings critical thinking aspects which help employees to have a wider exposure. The routine is in a pattern and stages where the initial stage is of observing the situations, and slowly the stages get increasing and from preparing plans and executing them with all the working employees at work station.

Life Cycle is in a way where the Critical Analysing takes place after that the industrial trends are identified and execution is done. The cycle goes in a loop where the motive or the objective remains the same but the rectifications and solutions are modified according to the idea that is constantly observing different industrial trends.

Recognizing, Preparing, Observing for changes, Maintaining, Updating, Modifying is the basic life cycle of Industrial Safety where the preparation as well as the ground survey is the primary focus of an individual to keep on doing this task in a repetition mode.

Industrial Safety Process

Process is something through which the task is carried out. The process involves the step by step procedure through which an Industrial safety officer decides how to make safety plans and create protocols.

The Do’s and Don’t are part of it where a list is prepared of guidelines and instructions which requires understanding of each employee without any misconfusion. Discussions, Meetings, Poster Distribution, Creation of Policies is all about the Industrial Safety Process.

Procedures are not only the lengthy and heavy protocols but it is the way or a pattern in which a work should be executed. Mis-match or irregular processes can affect the smooth running environment of an organisation.

All the minute details need to be added in the procedure, may it be employee safety or workstation tools safety, each and every detail should be inserted in the particular process. Legal Process, Compensation Process, Emergency Situation Process and Regulation Process are the ones which are involved in industrial safety.

Processes are always created in a dynamic stage where the changes are easily possible and through the emergency situations the process modification should be assured because the presence of mind can have some alternative safer process that can save for that particular moment.

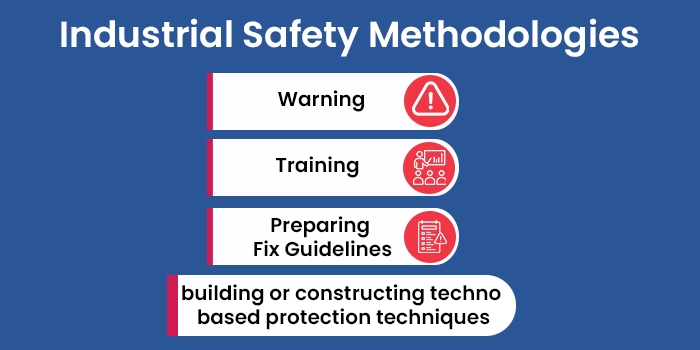

Industrial Safety Methodologies

Methods and Synchronisation is the key highlight of any organisation for building a safe workplace and for these there are some methodologies which are created by Industrial Safety Specialists. While creating a plan, an individual follows some theoretically correct methods and utilises some practical examples that are available in news and some critical mishaps.

In Simple terms some may follow the theoretical aspect of reading and pointer expanding method, whereas some may discuss the live examples for understanding the actual concept of the topic. The organisation always allows access to the workstation to have a perfect safe plan as it is for the employee and tools.

Preparing Fix Guidelines, Training, Warning, building or constructing techno based protection techniques. So if we talk about the methods- it has to be crystal clear that instructions are the serious follow methods and for it the preparation of Industrial Safety Guidelines are must.

Training sessions should be conducted to aware and guide the employees, crosschecking is required to have a look on danger creation situations and also if it purposely created then warning is mandatory. If there are any new easy and useful techniques for the safety measures then it can be added to the methodologies, as the technical assistance update boosts the positive environment.

Industrial Safety Tools

Tools basically refer to the equipment that are necessary while organising or preparing a safety kit. Majorly these tools are required in companies who have heavy and risky machines and to operate it the workers need safety kits to wear and protect themselves from injuries.

Before resuming work, employees are advised to wear a safety suit, hand gloves, Head Helmet, Working station Shoes and eye protector glasses and even a mask which will help to avoid the dust or particles entering inside the mouth.

The tools vary from work environment like if you visit a construction site then the labourers and engineers wear a safety jacket and a head cap which helps them stay away from dust and sun. For the workers who are in product packing are required to protect their hands and face so they have a tool which is like hand gloves and a whole safety suit which is mandatory.

Some of the Tools which are common and familiar are jotted below:

- Head Cap

- Hand Gloves

- Fire Protector Clothes

- Safety Suit

- Face Shield/ Surgical Mask

- Eye Protector Glasses

- Earbuds

- Foot Guard / Safety Shoes

Also remember the kit can have some more tools depending on the industrial work and type.

Power Tools Safety

Essential Measures which an individual or employee lacks are mishandling of tools provided for the safety purpose. The reason why this happens is due to the unawareness about the tool carrying or nobody is there to guide. Also the observed incidents mark that the employees hurry many times to just finish a work or to meet the deadlines and they end up injuring themselves where sometimes unfortunately life loss injuries are experienced. To guide and make the employees understand how to safely use the tools is a primary task which should never be avoided by an individual responsible to manage the industrial safety zone.

Industrial Safety Mistakes Observed Disaster

In India there are thousands of companies that have scary workstations , leniency and lack of awareness has damaged various 429 industrial setups as well as the 300 human loss of was a serious guilt. This section of information is added so that students get an overview that it's not an ordinary job, in fact it is a much more responsibility driven profile where the awareness and alertness should always be on. Check out the case studies around the world including India that can give you goosebumps. Safety Mistakes That Caused Disaster .

Industrial Safety Scope

Industrial workstations and hazardous locations are having a huge requirement for the safety executives and officers, as per this the scope is undoubtedly wide and in the coming future the scope will be more exaggerated as the demand is unavoidable. The learning trends are also changing according to the modern industry set up. Some new safety inventions are implemented to have a safe working zone.

- Conducting the Instructional Conversations will be beneficial for the field scope in the existing domain where your involvement in safety measures will be observed and it will add consistency in your task .

- Introducing or Identifying new tools and techniques will be praised as the dynamic route is designed for the betterment of the convenient working environment.

- Planned and Backup strategies should always be added for the critical situations and practising this in regular routine will increase your analysing skills.

- Workstations remain safe until the audit is regularly done and for this process the cross checking is must during the working hours and this will add credibility to your work and you can have a sustainable growth with a report graph of safety plans.

- Demos and Dangerous Situation Exit Practises should be carried out twice a month to monitor the situation and ensure that everything is safe , The environmental safety record is a move towards achievements.

Conclusion

Industrial Safety is a decent field which is one of the demandable areas of working. Demand and Requirement is increasing as the need for a safe and danger free environment has arisen the precaution management approach, if any individual is looking for an industrial safety option can have a fantastic career and also the training can help them to be a responsible professional in a particular field. There are ample job options available in industrial safety. The above article has all the important details in reference to industrial safety.

FAQs (Frequently Asked Questions)

Programs suitability depends on the students interest and accordingly there are a number of diplomas, bachelors, masters, PG Diploma degree programs available and different specialisations are also available mentioned in the above article.

The average salary package is around 4 LPA to 6 LPA which can go high according to the experience and interview round. Also different profiles can have different salary ranges as per the work and profile offered to a particular individual.

The chances are high one can grab the government placement opportunity by applying for the specific designation and according to the requirement a candidate be selected.

No, The fee range is minimal and also the practical training is affordable for those who want to have a career in Industrial Safety. The average fee range is from 5k to 50k depending on the university an individual selects for their training.

Idea Alchemist / Concept Creator / Insight Generator

We are an online education platform where users can compare 100+ online universities on 30+ X-factors in just 2 minutes. With an active CV community, we have transformed online learning to quite an extent. With the CV Subsidy scheme, we contributing to GER in India while helping our learners with their finances in their “Chuno Apna Sahi” journey!

Every query is essential.

Our team of experts, or experienced individuals, will answer it within 24 hours.

Recommended for you

Tired of dealing with call centers!

Get a professional advisor for Career!

LIFETIME FREE

Rs.1499(Exclusive offer for today)

Pooja

MBA 7 yrs exp

Sarthak

M.Com 4 yrs exp

Kapil Gupta

MCA 5 yrs exp

or

Career Finder

(Career Suitability Test)

Explore and Find out your Most Suitable Career Path. Get Started with our Career Finder Tool Now!

ROI Calculator

Find out the expected salary, costs, and ROI of your chosen online university with our free calculator.